Yamaha P-121 with Key that Doesn’t Play

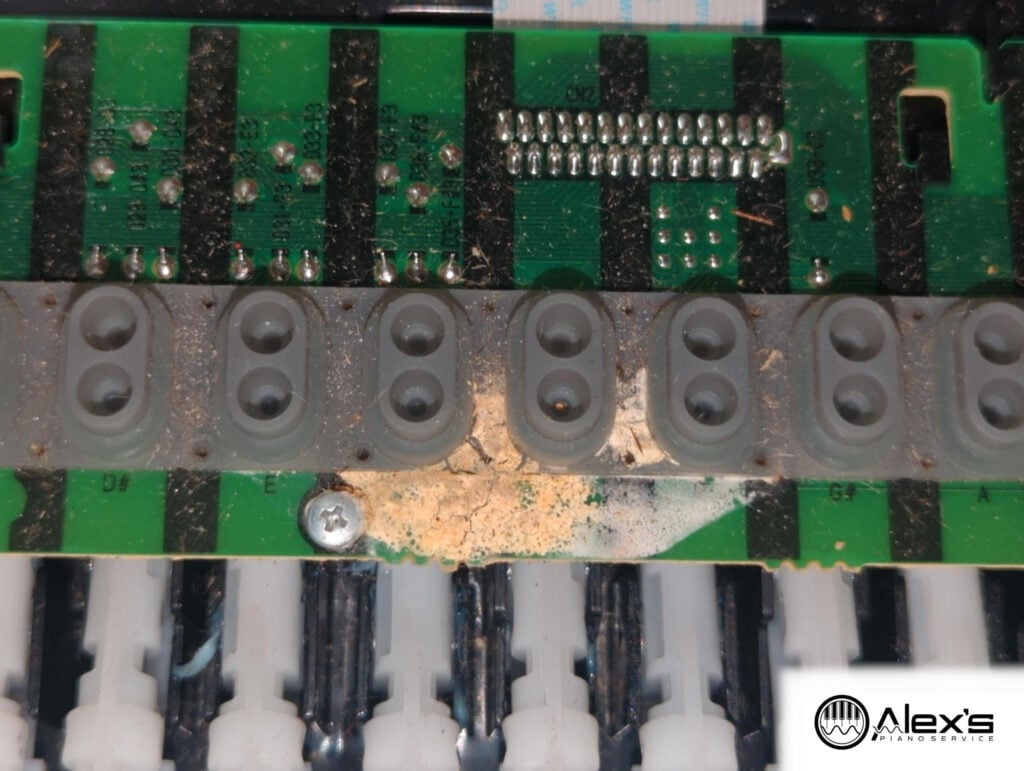

Two of the most common issues I encounter are keys that either don’t play at all, or play at full volume. Contact issues are, invariably, the cause. There are two parts involved in making proper contact: The rubber contact strips, which move and compress as the key moves, and the contact circuit boards underneath them. Spills damage both components.

I replace both the contact circuit board and the rubber contact strips. This prevents issues from developing in the future. Moisture issues often develop over the course of months or years after an event like this.

Cleaning a Yamaha DGX-660

The customer reported that there were many misbehaving keys in his Yamaha DGX-660, and that the speakers were buzzing. After opening the keyboard, I discovered that the buzzing was a consequence of hay and debris sitting on top of the speaker. Similarly, the misbehaving keys were caused by debris on top of the contacts, and also underneath them.

I use an Atrix Omega Supreme vacuum for cleaning out keyboard interiors. This is a very capable, static-safe vacuum cleaner that works in small spaces. Do not use a conventional vacuum cleaner, as these can produce static electricity and destroy nearby electrical components.

Gluing Peeling Hammers

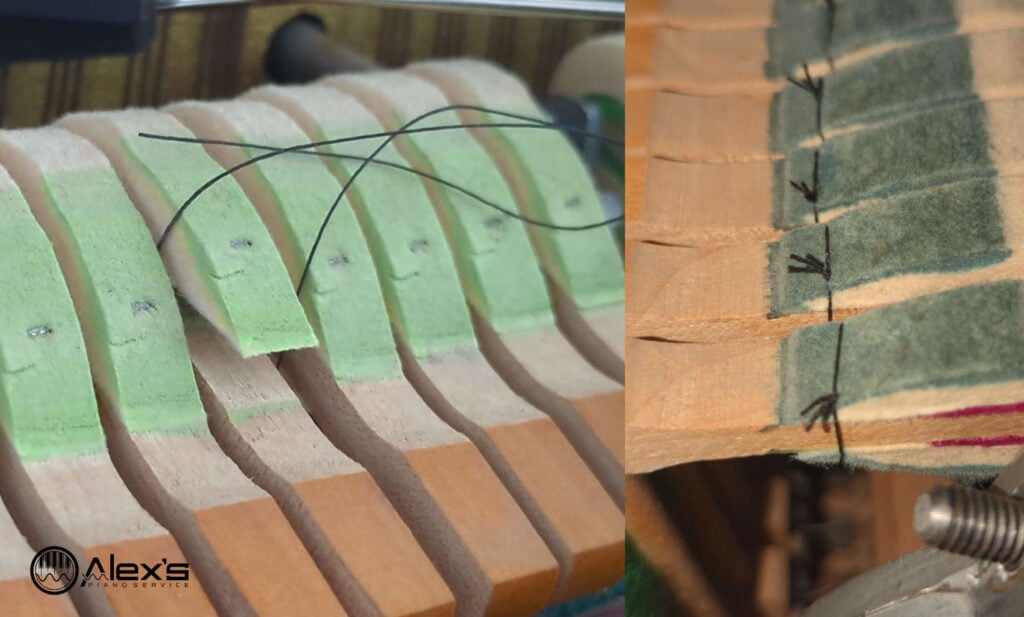

Sometimes I happen upon a piano with peeling hammers. This usually happens due to poor construction mixed with large humidity swings. In these cases, the best solution is to replace the entire set of hammers. However, in practice, replacing hammers is very costly—typically thousands of dollars. Worse, pianos with peeling hammers are typically lower value instruments.

What I do is apply a small quantity of hide glue or wood glue to the separated hammer surface. I then use upholstery thread to tightly bind the hammer felt to the surfaces. I secure the thread using a buntline hitch, which is relatively easy to tighten up and produces a strong bond. Use thread generously. You can cut the excess later, and it makes the knots easier to tie and set.

I also get good results with constrictor hitches; however, I find these somewhat harder to set securely, given the limited space between hammers.

Sometimes I have cleaned Yamaha strips if I am trying to get them through a gig till I get the new strips from Yamaha if I am out of stock. I have never had any (0)

luck cleaning Korgs, but pretty good luck on Yamaha’s although it’s a lot of time. I certainly would rather disassemble once not twice. Have you had any luck on KORGS, maybe there is a trick. I use 91 percent alcohol.

Sorry my name is Doug, and I am a tech in Grand Junction, the last of the techs in this area for about 200 miles. Also, do amp repair. Nice site you have. I also dig a lot of stuff out of keyboards 🙂

Hello Doug, and thank you for the kind words!

If there are large amounts of dry debris (such as in the DGX-660 pictured above), I’ll remove each set of rubber contacts and blast them at close range with compressed air. This is quick and surprisingly effective, without any of the risk of solvents or rubbing. If you’ve never done this, it’s very satisfying!

As a rule, if it’s a wet spill, I don’t put much faith in cleaning them, particularly if it’s something sticky. In a pinch, I’ll clean the contacts with 90%+ alcohol on a swab, and then blow it off with air to get rid of any particles. With wet spills, I also check the contact PCBs under magnification for discoloration or particulates, since wet stuff creeps into the graphite.

I concur: My success rate manually cleaning Korg contacts is much lower than with Yamahas, although I don’t know why. I’ve always just assumed the Yamaha design is somehow more forgiving.

That’s an interesting part of the country to work in. I’ve driven through Grand Junction a couple of times! I’m also in something of a “technician desert” up here, although not nearly so close to a literal desert.

73, WS1Q